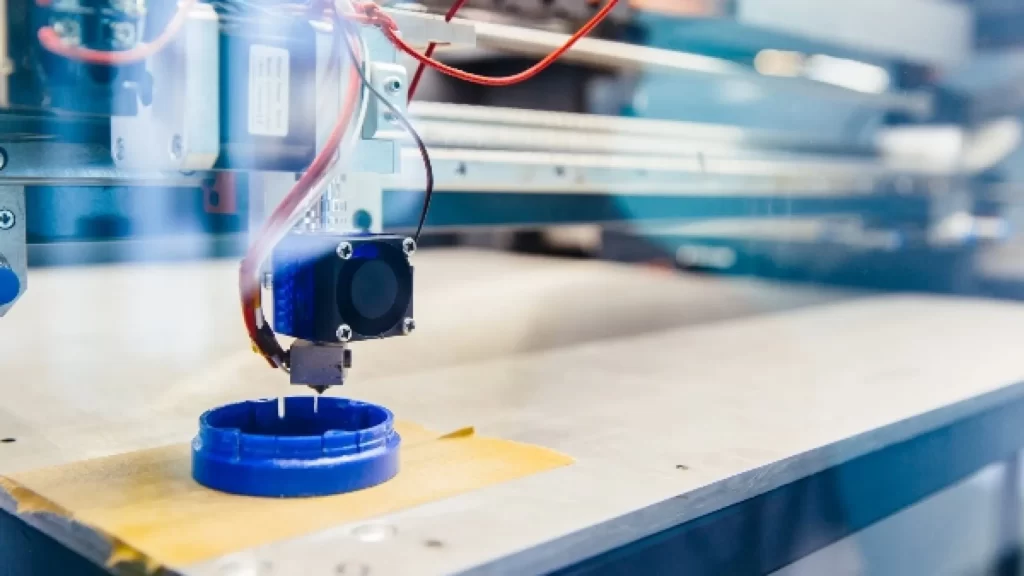

3D Printing

Providing precision 3D printing services with rapid prototyping, a variety of materials, and customizable options to turn your ideas into tangible, high-quality products.

Filament Types

Choose from a variety of 3D printing filaments, each tailored for specific strength, flexibility, and finish needs.

Capabilities

Our 3D printing capabilities include high precision, large build volumes, and customizable settings to suit any project requirements.

Speeds

We offer fast 3D printing speeds without compromising on quality, ideal for both prototypes and final products.

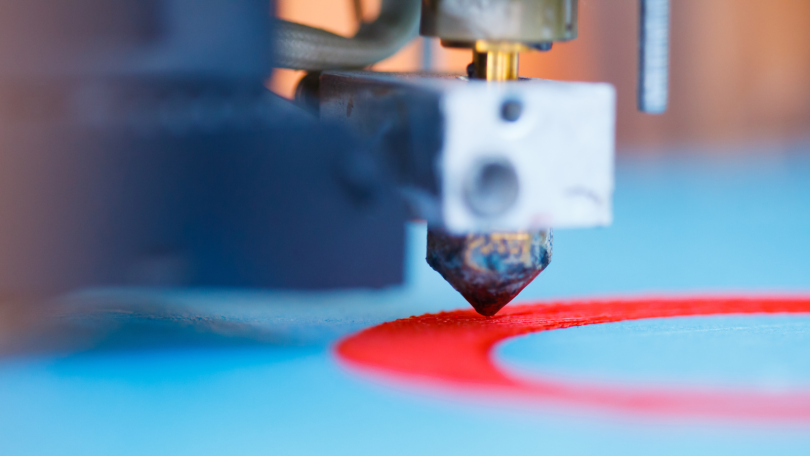

Exact Detail

3D printing delivers precise, high-resolution details, ensuring every model is accurately replicated from digital designs.

Detail

3D printing delivers precise, high-resolution details, ensuring every model is accurately replicated from digital designs.

Resolution and Accuracy

Achieving higher detail in a 3D print requires a finer resolution, meaning the printer must be capable of producing smaller, more precise layers. This allows for greater accuracy in replicating intricate features, ensuring the final print meets the desired level of detail and smoothness, especially for complex designs.

Material Considerations

Detailed prints often require specific materials that can accurately capture intricate features without warping or distortion. These materials are essential for maintaining the precision and fine details of the design, ensuring that the final result reflects the intended look and functionality.

Support Structures

Detailed prints, on the other hand, often require more complex support structures to stabilize fragile or overhanging features. Therefore, these supports must be carefully designed to ensure the fine details remain intact and undamaged.

Post-Processing

High-detail prints often require additional finishing steps, such as sanding, painting, or smoothing, to ensure that the intricate features are clear and clean, especially if the printing technology leaves visible layer lines.

Filament Types

Different filaments can significantly affect the 3D printing process in terms of print quality, speed, material properties, and post-processing requirements. Here’s how various types of filaments influence the process

PLA

PLA is one of the easiest filaments to work with. it can also produce high-quality prints with good detail, but its surface finish can be slightly less smooth compared to other materials.

ABS

ABS is stronger and more heat-resistant than PLA, making it suitable for functional parts and mechanical components.ABS tends to warp more during printing, especially on large prints

PETG

PETG offers the strength of ABS while maintaining the ease of use of PLA. It is durable, flexible, and moisture-resistant, making it ideal for both functional parts and outdoor applications.

TPU

TPU is a flexible filament, making it suitable for parts that need to bend or stretch (e.g., phone cases, seals, or flexible gaskets). Printing with TPU can be challenging because of its flexibility. It requires slower printing speeds

Speeds

Finding the right balance between print speed and quality is crucial. For high-quality, detailed prints, it’s best to use slower speeds, especially for intricate designs or functional parts.

Print Quality

Printing at higher speeds can lead to a decrease in print quality. When the printer moves too quickly, the layers may not bond as well. Slower print speeds tend to produce higher-quality prints. The nozzle has more time to extrude filament consistently.

Filament Flow and Extrusion

When the extrusion speed exceeds the printer’s capability, the filament may be deposited too quickly. As a result, excess material can ooze or overflow, leading to issues like blobs or stringing on the printed object.

Overhangs and Support Structures

Printing quickly may struggle with overhangs or unsupported features, as the filament may not have time to cool and solidify before the next layer is applied.

Accuracy and Precision

At faster speeds, the printer may not be able to maintain consistent accuracy, especially on curves or small features, due to the motion instability or reduced extrusion control.

Capabilities

The capabilities of the 3D printing process are vast, allowing for a wide range of applications across industries, from prototyping to end-use parts. Below are some of the key capabilities:

Complex Geometries

3D printing allows for the creation of highly complex geometries that would be difficult, if not impossible, to achieve with traditional manufacturing methods. It enables highly customizable designs, whether for one-off prototypes, personalized products.

Rapid Prototyping and Iteration

With 3D printing, rapid prototyping becomes possible, drastically cutting the time needed to create physical models. Instead of waiting weeks with traditional manufacturing, models can be produced in just hours, accelerating the entire process.

Material Flexibility

A wide variety of materials can be used in 3D printing, including plastics like PLA, ABS, and PETG, along with metals such as stainless steel and titanium. Moreover, it supports resins, composites like carbon fiber and glass-filled materials, and even unique options such as ceramics and food, making it highly versatile.

Reduced Waste

As an additive process, 3D printing deposits material only where it’s needed, which helps minimize waste. In contrast, subtractive manufacturing removes excess material, often leading to significantly higher waste levels.

Nashville, Tennessee, USA | Phone: 800-453-3801 | Email: info@zagnat.com

Copyright © 2025 Zagnat